:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093 产品展示

产品展示

服务热线

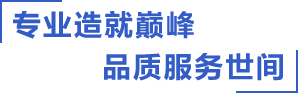

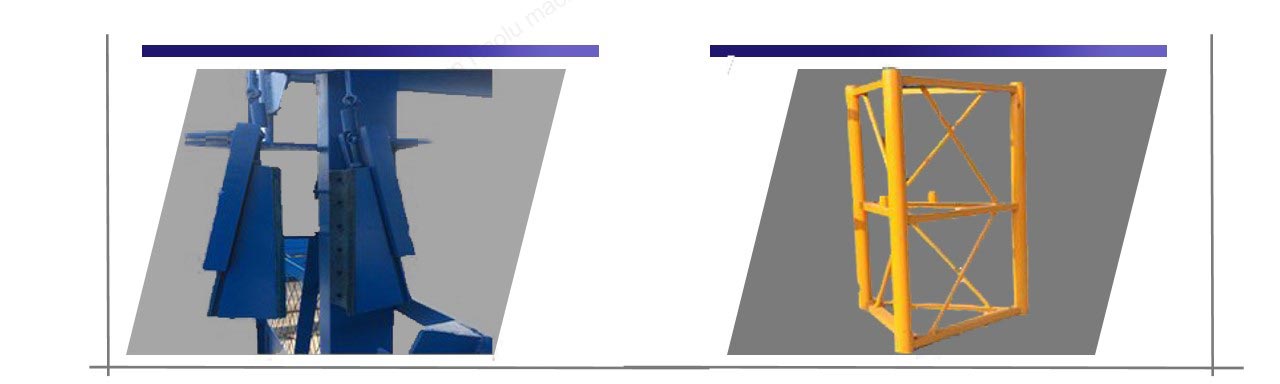

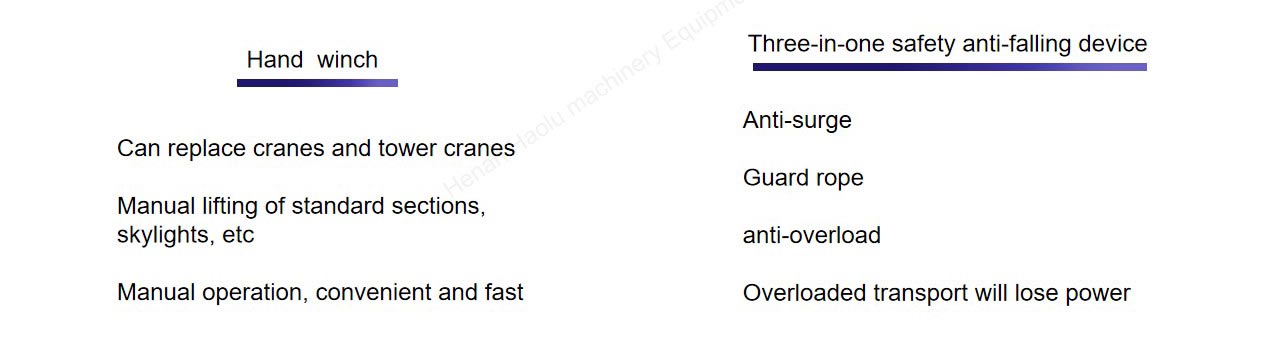

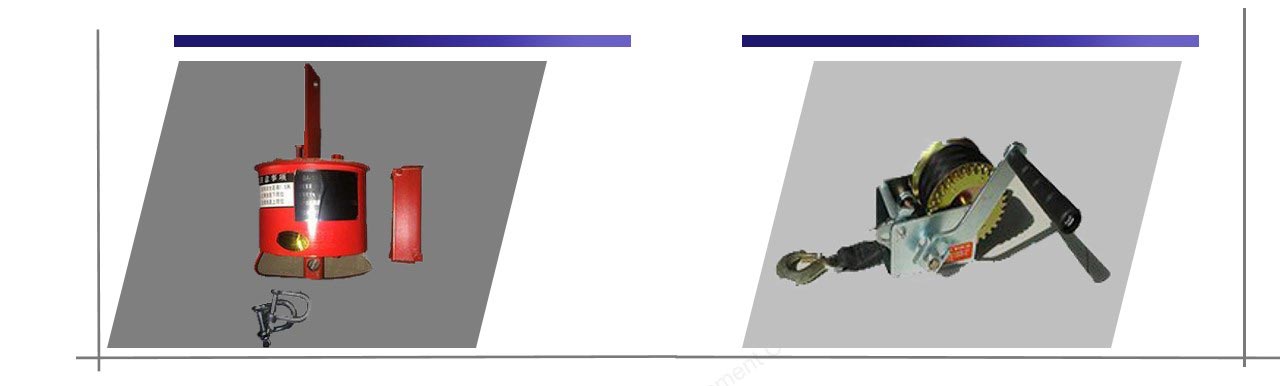

SS1T material elevator single cage construction elevator is composed of bottom frame, lifting cage, standard joint attachment device, sky beam and derrick, transmission system, anti-fall safety device. The machine is connected to the wall through the attachment frame, without wind rope, especially in the narrow site construction. Each lifting cage is equipped with safety anti-fall device and stoppage device and overload protection. This machine is suitable for multi-layer workshops and vertical transportation of materials in construction and mining enterprises. It has the advantages of fast installation and disassembly, safe and reliable use and high efficiency.

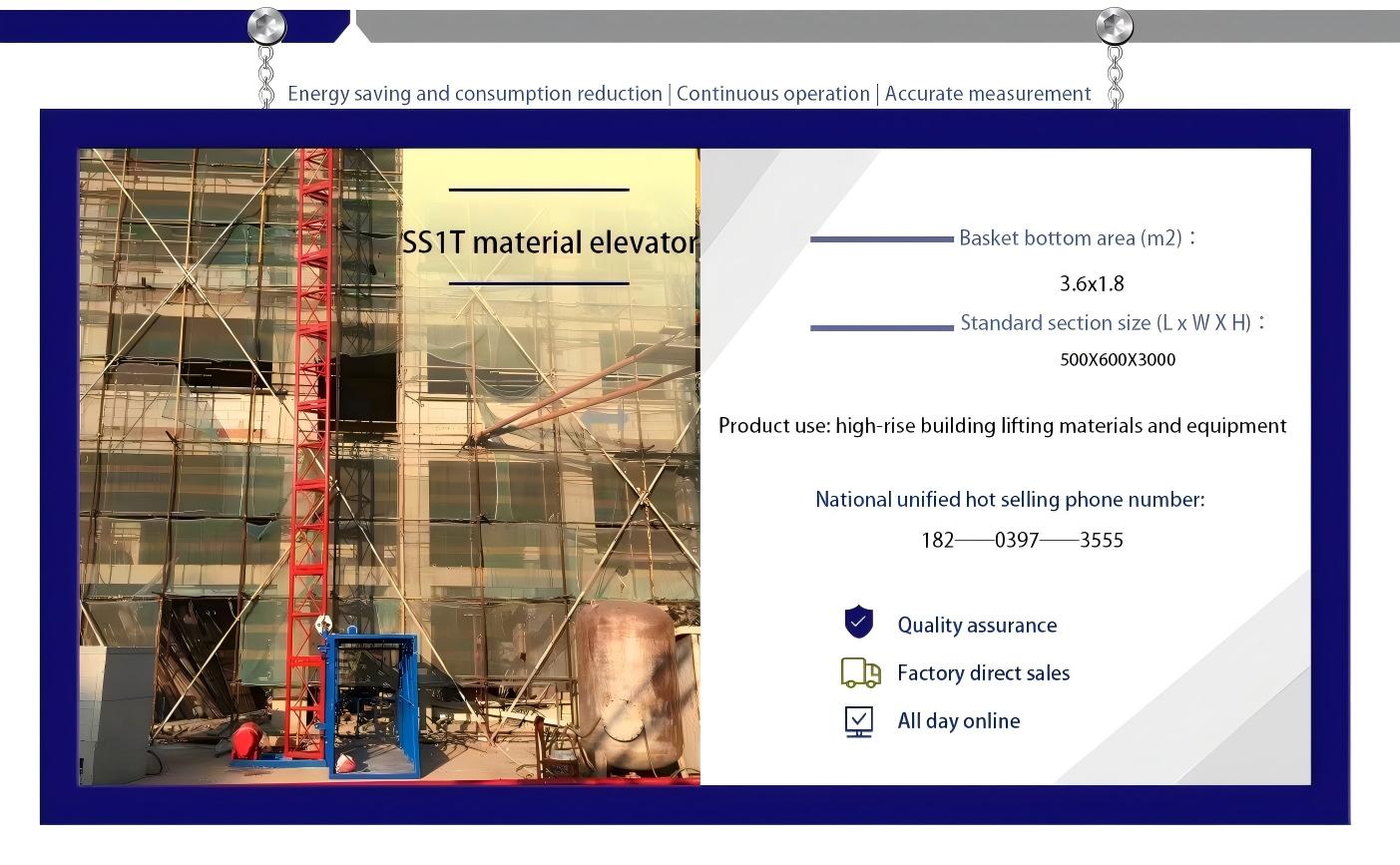

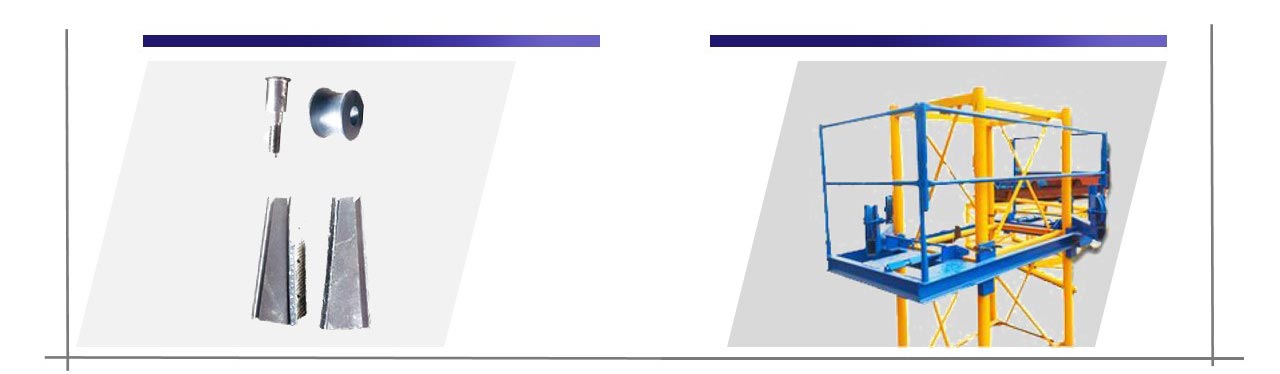

SS1T material elevator Part Detail Diagram

SS1T material elevator, detail picture

SS1T material elevator, main features

1. A single cage and double cage construction lift: a single cage lift such as adding a lifting cage and other parts can become a double cage lift

2.0~90 meters high speed frequency conversion construction elevator. The maximum running speed can be up to 96 meters per minute. using 800×800×1508 standard section, for high-rise construction sites can save a lot of time to improve work efficiency, and more stable and reliable.

Now there are more low-speed frequency conversion construction elevator, running speed of 0-36m per minute.

3. Inclined construction lift. For Bridges, towers and other small under the large Angle of the building is particularly suitable, the maximum tilt Angle can be up to 9 degrees, it is along the inclined plane of the building to run up, to further ensure the smooth operation of the construction of the lift, the length of the attachment point is easy to install..

Usage and Maintenance

1. Check every bolt fastener weekly for any looseness, and if there is looseness, tighten each bolt in a timely manner. Check if there is deformation in each steel structure and if there are cracks in the welds.

2. Check weekly whether the electrical system is working properly, whether the AC contact points are closed, and whether the wire joints are in good condition.

3. Before each operation, check if there are any protrusions on the running channel of the cage to ensure that the safe distance of the cage is not less than 250mm.

4. Before each operation, check whether the guide wheel is loose and whether the gap with the guide rail is normal. If it does not meet the requirements, it should be adjusted in a timely manner.

5. Check the lubrication condition of each part every week, add lubricating grease in a timely manner, and inspect the wear condition of the steel wire rope, and handle it according to the "Specification for Inspection and Scrapping of Steel Wire Ropes for Lifting and Reuse".

6. Regularly check the winch for oil leakage.

7. Regularly check the load-bearing condition of the suspended cage floor, and promptly replace and repair it.

8. After each dismantling of the material elevator, a comprehensive inspection and maintenance should be carried out.

9. After each new installation, it is necessary to check whether the action of the anti fall safety device is reliable (completed through the anti fall test). Henan Haolu Machinery Equipment Co., Ltd

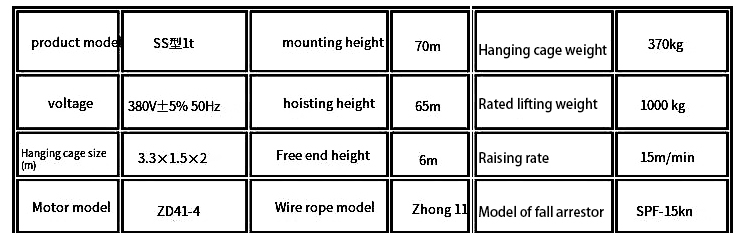

SS1T material elevator, parameters

SS1T material elevator, field case