:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093 产品展示

产品展示

服务热线

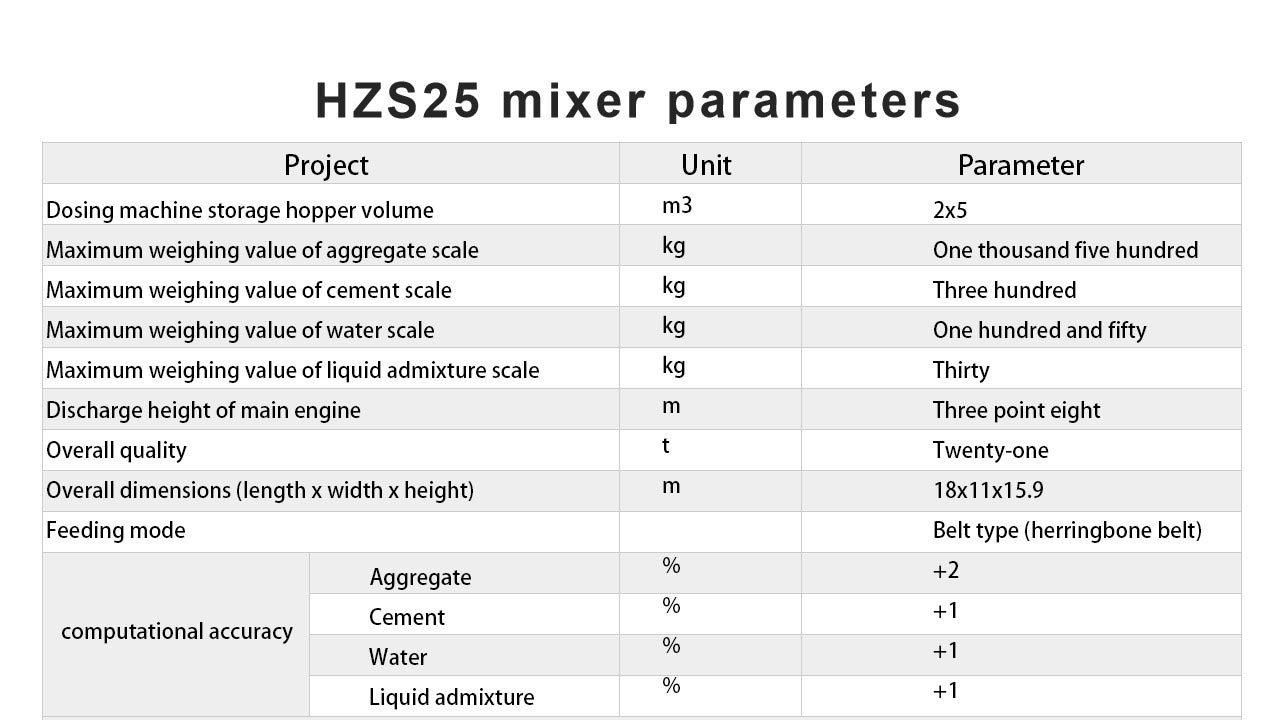

HZS25 immersion concrete mixing station is a simple and small-scale sample mixing station equipment with automatic feeding function, and it is a semi-automatic concrete mixer composed of S500 forced loss mixer, material supply, fabric electrical control and steel structure. This simple mixing has the dual advantages of independent use of single machine and PLD series drawing machines to form a sample mixing station with a production capacity of more than 25m3h. It is also simple in structure, convenient to disassemble and construct, uniform in concrete loss, short in mixing time and long in damaged parts life. It is suitable for small-scale construction sites, prefabricated factories, small-scale commercial concrete production plants and highway maintenance. It adopts new design ideas, electronic weighing, microcomputer control, digital display and other control technologies. The electronic weighing has embroidery device and automatic compensation function, and the measuring accuracy is high. The gravel feeding system uses a wide herringbone belt to feed.

HZS25 concrete mixing station, the representative of high-efficiency engineering concrete mixing station, is a small mixing station equipment, also known as 25 mixing station, which is a semi-automatic concrete mixing machine composed of feeding, batching, mixing, electrical control and steel structure parts. Xinfeng machinery HZS25 mixing station is developed by combining the latest technology at home and abroad, which is suitable for the needs of customers, small-scale construction sites, prefabricated factories and commercial concrete production plants, and is more suitable for the supply of concrete with strong mobility such as railways and highways.

HZS 25 Part Detail Diagram

Safety precautions of commercial concrete mixing station

1. During installation, it is forbidden to tilt the warehouse body and deform the legs.

2. The bottom of the leg is welded firmly with the embedded parts of the foundation.

3, do a good job of wind and lightning protection.

4, it is forbidden to strongly impact the legs and the warehouse.

5, regularly check the cement adhesion of dust collector bag, clear in time.

6, the foundation must be solid, in line with the architectural design specifications.

7. Once the bag is blocked and the pressure in the warehouse exceeds the safety pressure of the pressure safety valve at the top of the warehouse, the pressure safety valve can be opened to release the pressure in the warehouse to prevent the warehouse from bursting.

8. When the cement silo (cement silo) is working, it must be erected by a special crane, and then placed on the pre-fabricated concrete foundation. Check the verticality of the cement silo (cement silo) with the horizontal plane after it is erected, and then weld its bottom firmly with the embedded parts of the foundation.

On site case of HZS25 concrete mixer

On site case of HZS25 concrete mixer