:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093 产品展示

产品展示

服务热线

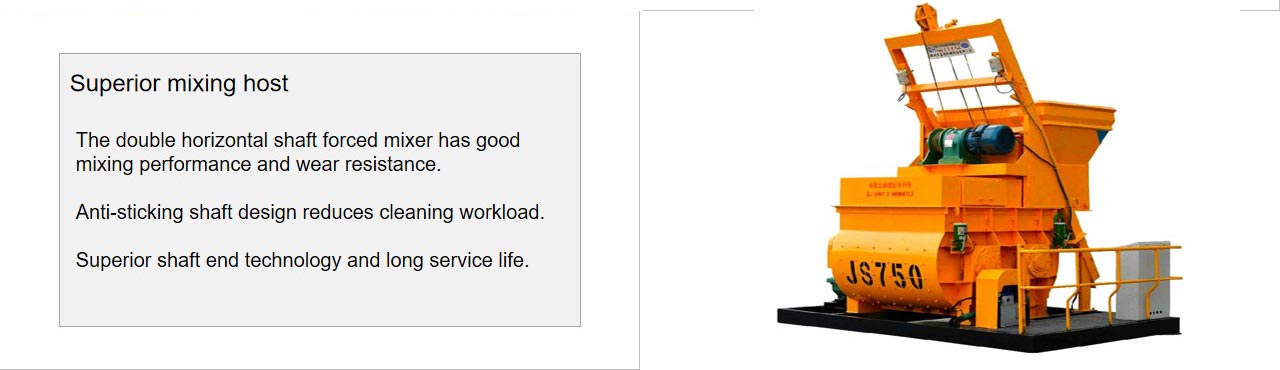

HZS35 concrete mixing station is a small concrete mixing station, which is often called 35 stations by customers. The production line configuration of this set of concrete mixing station is mainly composed of main engine, dosing machine, screw conveyor and other related products, and its theoretical productivity is 35 m3/h. The concrete mixing station is mainly divided into four parts: sand and gravel feeding, powder feeding, water and admixture feeding, transmission, stirring and storage. The whole equipment is cast in integral steel structure, and the high-quality H-beam not only has beautiful appearance, but also strengthens the overall structural strength of the concrete mixing station, and the equipment can be installed conveniently, which can be applied to various complex terrain structures.

HZS35 concrete mixing station Haolu mechanical mixing station series miniaturized mixing station products. The semi-automatic concrete mixing station is composed of hopper feeding mode, material feeding, batching, mixing, electrical control and rigid structural components, which can conveniently and efficiently contain and dump aggregate, greatly reduce the occupied area of the site and save up to one-half to two-thirds of the land occupied area. HZS35 concrete mixing station equipment can be installed in two to four days. With less equipment, wide application range and theoretical productivity of 35 cubic meters per hour, it is an ideal station-building equipment for bridge construction, road engineering, construction sites and component companies.

HZS 35 Part Detail Diagram

Performance advantage

1. Quick installation

The installation method of HZS35 concrete mixing station is steel beam. It takes only a few hours for the main system to be unloaded and installed, and it takes only two to four days for the installation of other supporting facilities such as control room and batching station to be completed and ready for production.

2. Reasonable design

The design of mixing platform, metering platform and lifting system platform of HZS35 concrete mixing station is very reasonable, which fully guarantees the demand of inspection and maintenance equipment. When the external protective layer needs to be installed, enough space for daily work can still be ensured.

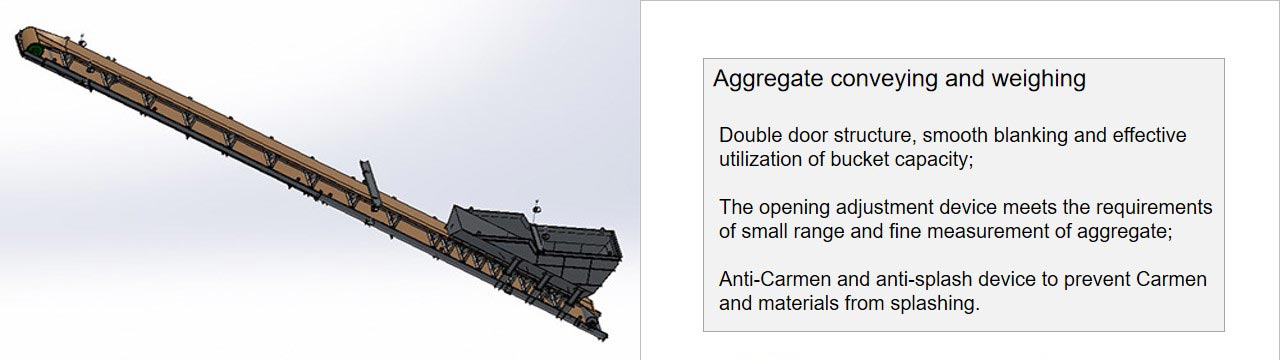

3. Less floor space

HZS35 concrete mixing station uses belt or bucket to feed. The design of belt and hopper can efficiently load and dump aggregate and greatly reduce the occupied area of the site.

4. Less investment and simple maintenance

HZS35 concrete mixing station has the advantages of less capital, small occupied area, less equipment, simple equipment maintenance and safe and convenient equipment operation.

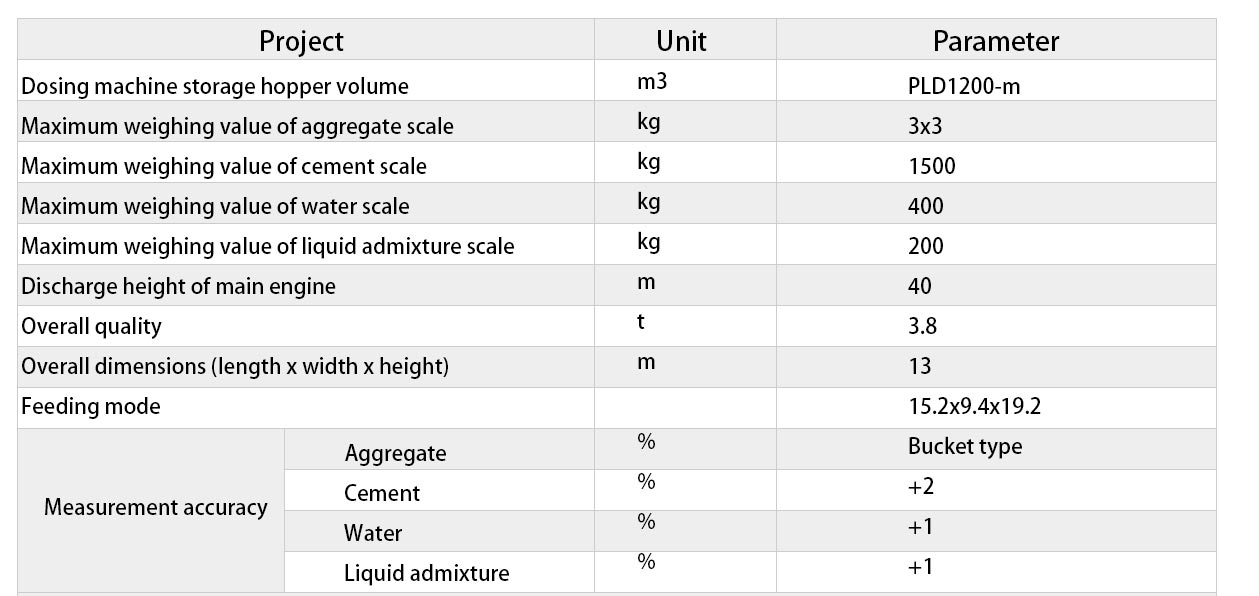

HZS35 mixer parameters

On site case of HZS 35 concrete mixer