:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

:+86-13598440093

![]() JS2000 concrete mixer discharges 2 square meters at a time, which is also called 2-square concrete mixer and 2-square mixer. JS2000 concrete mixer is mainly used as the main machine of HZS120 concrete mixing station, with a feeding capacity of 3200L, a discharging capacity of 2000L, a theoretical productivity of 120 cubic meters per hour and an aggregate particle size of 80/60 mm; Suitable for mixing plastic, hard and lightweight aggregate concrete and various mortars and mortars. This concrete mixer adopts motorized discharging, which can be used together with the dumper. It is a tool for various construction sites.

JS2000 concrete mixer discharges 2 square meters at a time, which is also called 2-square concrete mixer and 2-square mixer. JS2000 concrete mixer is mainly used as the main machine of HZS120 concrete mixing station, with a feeding capacity of 3200L, a discharging capacity of 2000L, a theoretical productivity of 120 cubic meters per hour and an aggregate particle size of 80/60 mm; Suitable for mixing plastic, hard and lightweight aggregate concrete and various mortars and mortars. This concrete mixer adopts motorized discharging, which can be used together with the dumper. It is a tool for various construction sites.

![]() JS2000 Mixer is suitable for mixing hard concrete, plastic concrete, flowing concrete, lightweight aggregate concrete and various mortars in all kinds of large, medium and small prefabricated component factories and industrial and civil construction departments such as highways, bridges, water conservancy, ports and docks. JS2000 concrete mixer is usually combined with PLS3200 dosing machine and other equipment to form a mixing station.

JS2000 Mixer is suitable for mixing hard concrete, plastic concrete, flowing concrete, lightweight aggregate concrete and various mortars in all kinds of large, medium and small prefabricated component factories and industrial and civil construction departments such as highways, bridges, water conservancy, ports and docks. JS2000 concrete mixer is usually combined with PLS3200 dosing machine and other equipment to form a mixing station.

JS2000 Part Detail Diagram

Js2000 site decomposition

Principle of operation

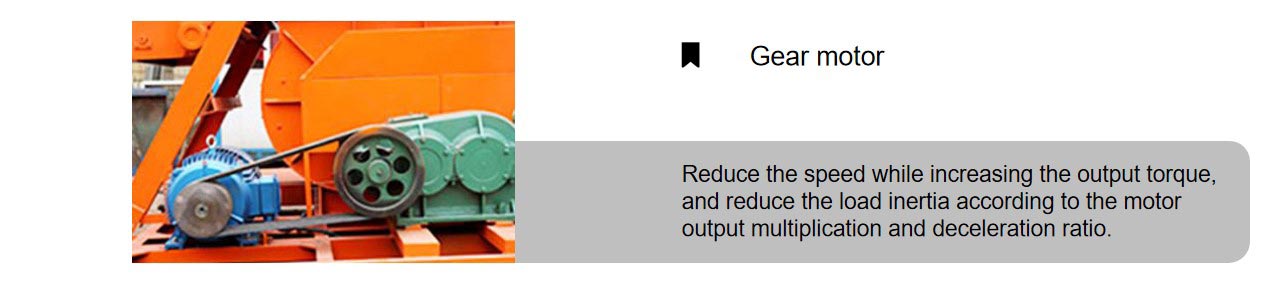

JS2000 concrete mixer is composed of feeding, mixing, discharging, water supply, electricity and other parts.

1. Mixing system

The four observation covers on the mixing drum can be pushed out towards each other after being lifted 90 degrees.

2. Feeding system

The feeding system consists of a hoist mechanism, a feeding gantry, a hopper and a feeding nozzle.

The brake motor drives the drum to rotate through the reducer, and the steel wire rope pulls the hopper up along the feeding rack track through the pulley. When it climbs to the height, a pair of rollers on the bucket door at the bottom of the hopper enter the feeding rack water track, and the bucket door automatically opens, and the materials are thrown into the mixing drum through the feed nozzle.

3. Water supply system

The water supply system consists of water pump, throttle valve, cleaning device and spraying device.The throttle valve is driven by the cylinder to adjust the water-saving flow, and the total amount of surface water supply is adjusted by the electronic scale.

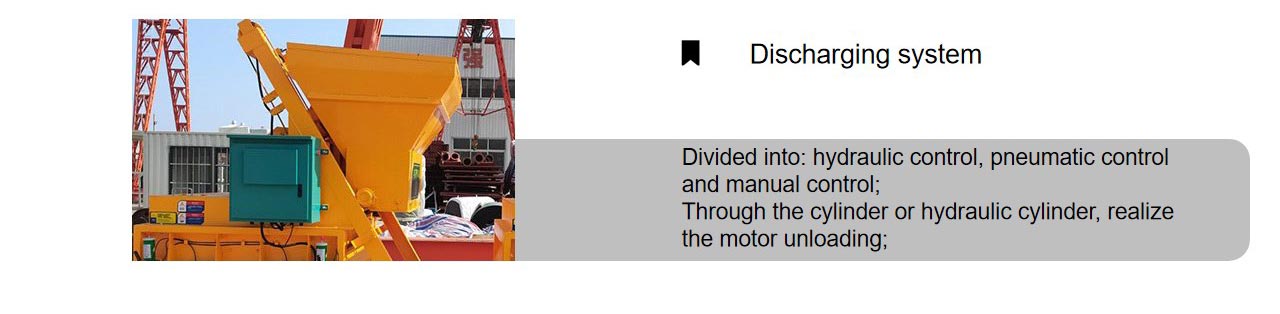

4. Unloading system

The discharging system is composed of discharging unit 6, air pump, reversing valve, air distribution valve, air cylinder, and electric mechanism. The discharge door is installed at the bottom of the mixer, and pneumatic discharge is realized through the cylinder. And the opening and closing position of the discharging door, and the sealing of the discharging door can be ensured by adjusting the position of the sealing strip. JS2000 unloading manual operating lever is used for emergency unloading in case of temporary power failure and unloading in case of cylinder failure. It should be removed at ordinary times to prevent personal injury.

5. Electrical system

The electric control power supply is 380V three-phase four-wire power supply, and the allowable voltage error is 10%, otherwise it is prohibited to use. If users bring their own electric power supply, the capacity should be ≧100KVa. The surface temperature rise of the motor is ≦60℃, and the live part is insulated from the shell by ≧0.5MΩ.

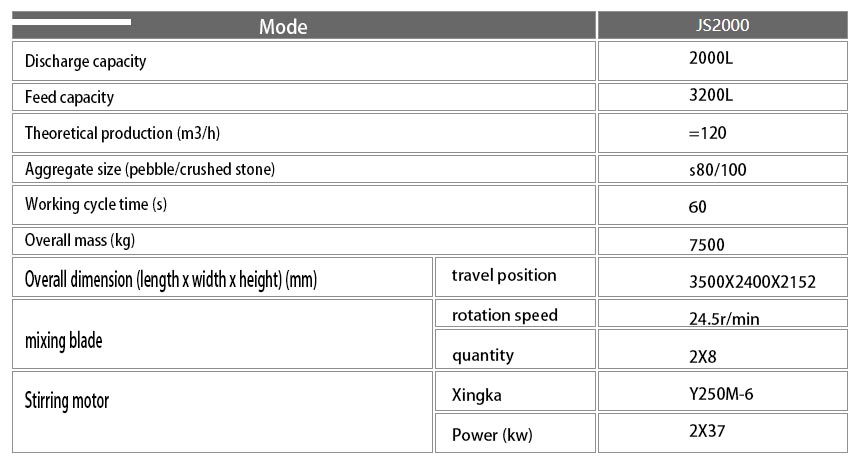

JS2000 mixer parameters

On site case of JS2000 concrete mixer